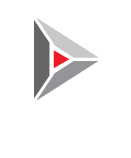

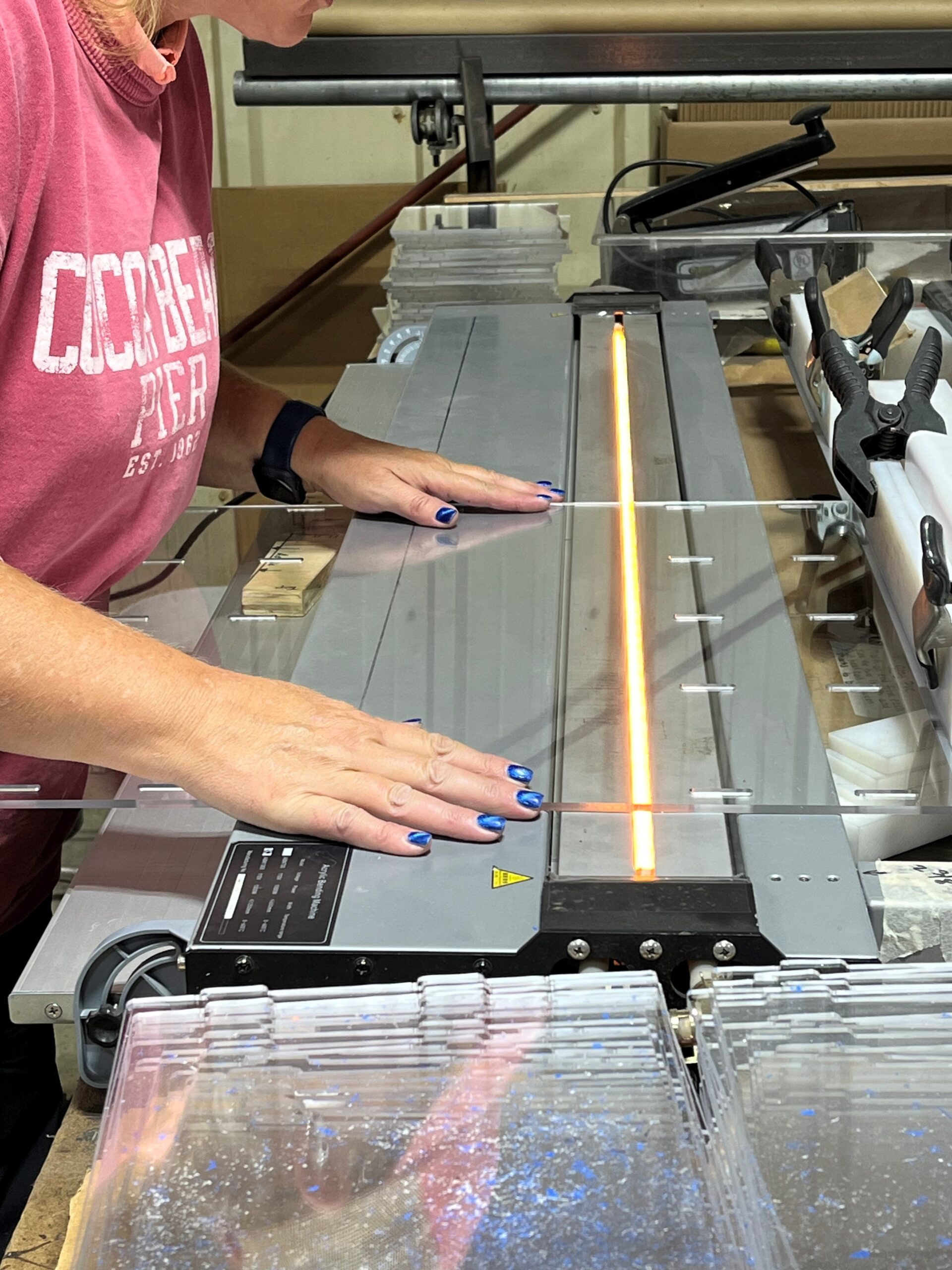

heat bending

WHAT IS HEAT BENDING?

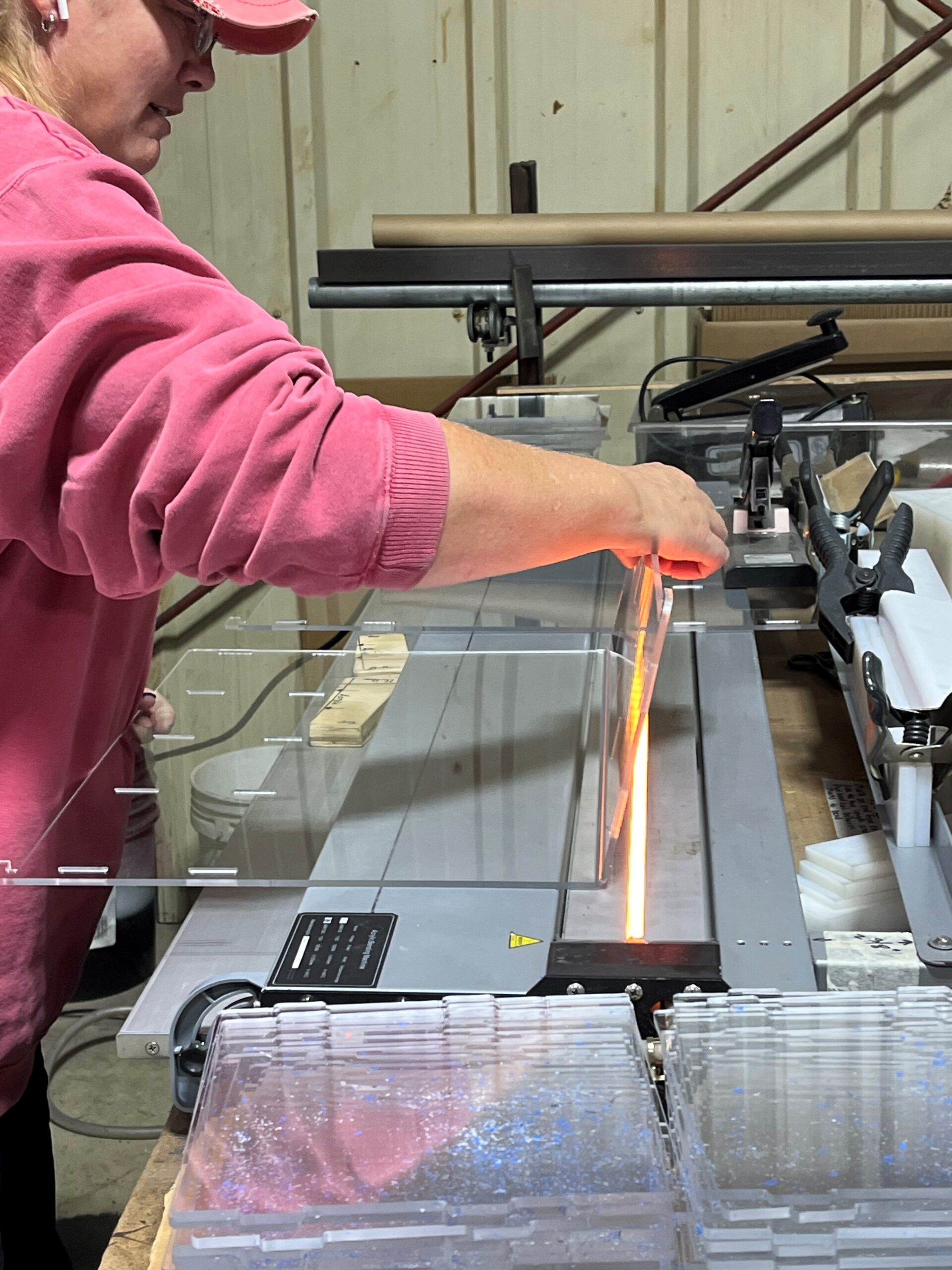

Heat bending is a plastic manufacturing method in which a thermoplastic sheet is placed on a positive/male mold and then heated to its softening point so that the sheet’s weight or pressure applied by an operator causes the plastic to take the shape of the mold.

ADVANTAGES OF HEAT BENDING

- It is both affordable and time efficient.

- Heat Bending requires minimal tooling, generally only fixture systems.

- The original composition of the material remains mostly intact which allows the part to maintain maximum strength.

- It works with most plastic material.

- Simple way to bend material in half or at a specific angle.

- Clear or textured material retains its characteristics.

MATERIALS OFTEN USED IN HEAT BENDING

- Acrylonitrile Butadiene Styrene ABS

- Polycarbonate PC (Lexan®)

- Polyethylene terephthalate PET

- Polyethylene terephthalate glycol PETG

- Polymethyl Methacrylate PMMA (Acrylic, Plexiglass)

- Polystyrene PS (HIPS)

- Polyvinyl Chloride PVC

Will heat bending work for your thermoforming project? Contact us to find out.