the project process: from concept to reality

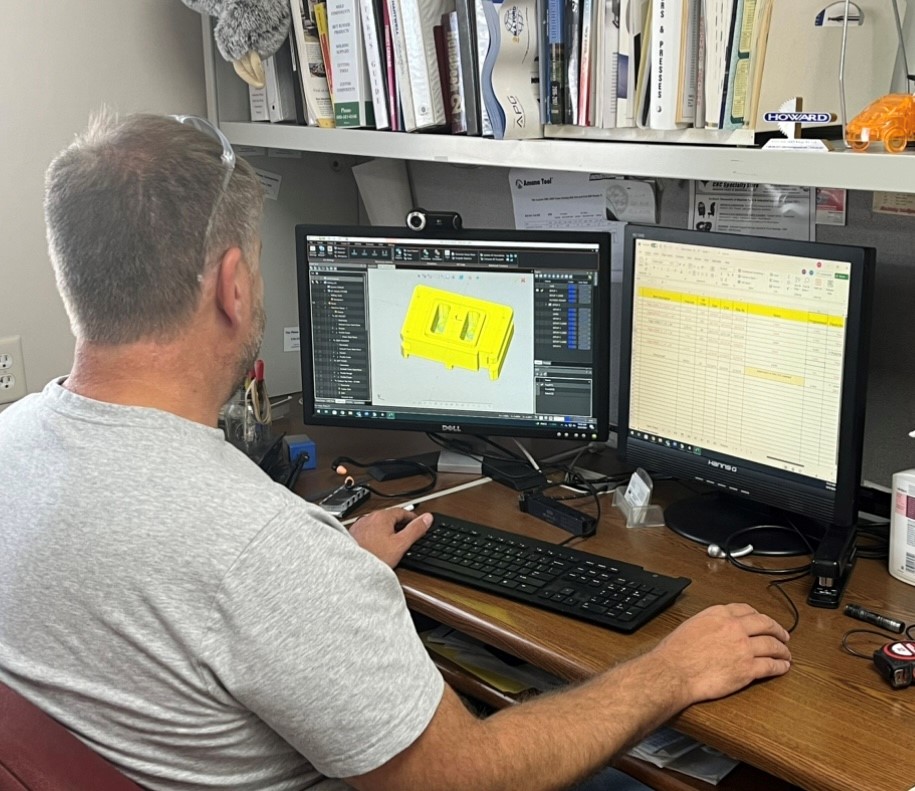

Designing & Prototyping

Most often, customers come to us with a completed CAD drawing or model of their project. However, QC Plastics is happy to assist you with these steps if needed.

Material Selection

Whether you have already chosen the material for your project or need help with the selection process, QC Plastics is ready to assist you. We have experience working with many types of plastic materials and are always interested in trying something new. QC Plastics can guide you to make the right material choice aesthetically, functionally, and financially.

Tooling

QC Plastics can work with your existing tools or create molds and trim fixtures for you. We can help you choose the best tooling material (such as wood, foam, aluminum) for your project and even combine multiple parts on the same mold, when feasible, to save you money.

Production

Our team will work with you to come up with the best production method for your project whether it is thermoforming (vacuum forming, drape forming, heat bending) and/or trimming using our routers, mills, and lathes.

QC Plastics can also assist you with light assembly and other final fabrication services such as metal embedment (e.g. inserts, threading), hardware assembly, plastic welding, bonding/gluing, and packaging/kitting.

Inspection

During the production process, your parts will go through an inspection procedure multiple times to ensure accuracy.

SHIPPING

When your project is completed, we will package it according to your specifications and ship it to you.

PARTNERSHIP

Whether your project is big or small, our sales team will be beside you each step of the process, communicating any issues that may arise and responding quickly to your requests.

Contact us if you are ready to start your project with QC Plastics.